The global economy is undergoing a seismic shift, driven by the accelerating demand for critical minerals, the building blocks of battery technology, defence systems, infrastructure, and the clean energy transition. In response, governments worldwide are implementing powerful incentive programs, such as the U.S. Inflation Reduction Act (IRA) and Australia’s Critical Minerals Production Tax Incentive, to secure stable, domestic supplies and de-risk investment in this capital-intensive sector.

For South Africa, with its vast deposits of essential elements like chromium, manganese, and vanadium , these global movements present a massive opportunity to accelerate local industrialisation and beneficiation, extending far beyond the mines and directly impacting local manufacturers.

The Domino Effect: From Mine to Market

While the direct beneficiaries of global incentives are mining, exploration, and processing firms, the true economic impact is the ripple effect across secondary and downstream industries.

The Diverse Spectrum of Criticality

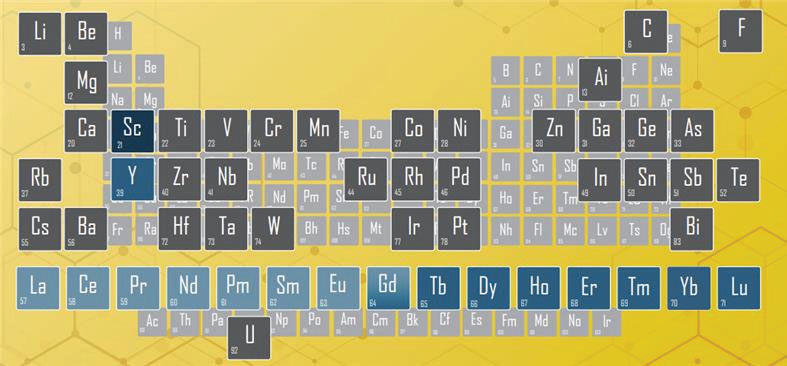

The transition to a clean energy future requires a staggering array of materials, many of which are designated as Critical Minerals due to their economic importance and high risk of supply disruption. South Africa’s mineral wealth is diverse, encompassing key elements vital for global battery and permanent magnet technology. Understanding the full spectrum of these materials—from Aluminum and Lithium to the Rare Earth Elements—underscores the strategic importance of secure, domestic processing.

The Critical Minerals Table visually represents the elements underpinning the global high-tech and green economy, illustrating the vast scope of the mining and processing challenge worldwide.

The economic stimulus generated at the initial mining and processing stage does not stop there; it creates a powerful and integrated industrial ecosystem. By de-risking new mining projects and mandating greater regional sourcing, these global and local incentives create guaranteed demand and stability, pulling investment into the downstream sectors. This ensures that the wealth generated from South Africa’s mineral resources flows directly into local manufacturing and high-value beneficiation industries, establishing resilient supply chains from mine to finished product.

- Stimulating the Supply Chain: Incentives for mineral production, such as tax credits and loan guarantees, make it financially viable to explore and expand domestic processing facilities. South African policies, including the MPRDA (Mineral and Petroleum Resources Development Act), also aim to improve access to mineral rights and foster policy reform for governance in the sector, leveraging the African Mining Vision (AMV).

- Boosting Local Beneficiation: A secure, local supply of processed critical minerals (like refined lithium or nickel) is a magnet for downstream beneficiation industries. Companies in the automotive, aerospace, defence, and electronics sectors are incentivised to build new plants and expand operations where they can access this cost-effective and secure supply.

- Driving Specialty Chemicals: The massive scale of critical mineral processing requires specialty chemicals, such as Sulfuric Acid, Hydrochloric Acid, and Sodium Hydroxide. As mining and refining operations ramp up, demand for these chemical producers is projected to soar, opening a multi-billion dollar opportunity for South African manufacturers in this space.

Flexicon: The Critical Link for South African Industry

The transition to a highly integrated, domestic supply chain hinges on the ability to safely, efficiently, and consistently handle the bulk materials throughout the processing and manufacturing cycle. This is where local manufacturers like Flexicon Africa become a critical link.

Flexicon, with manufacturing facilities in South Africa, provides the essential bulk handling equipment required to manage these challenging materials:

- Bulk Bag Fillers: Designed to fill bags with abrasive materials like dressed ore with high precision and stability, often handling up to 2,000 kg. Their automated, dust-tight systems ensure product consistency for transport and further processing.

- Bulk Bag Dischargers: Crucial for safely dispensing difficult-to-handle minerals, including those prone to caking or clumping, using features like integrated Bulk Bag Conditioning and advanced flow control valves to prevent spillage and dust.

- Flexible Screw Conveyors: Used to transport raw and processed materials like filter cake and dry chemical additives (leaching or water treatment agents) efficiently and dust-free between stages.

The ability of South African mining houses to automate and de-risk their material handling processes directly supports the growth of secondary local manufacturing by ensuring a reliable and consistent material flow.

Conclusion

Global critical minerals incentives are more than just foreign policy; they are a powerful external driver for South Africa’s own economic agenda. By stimulating investment in the foundational mining and processing sectors, these global trends create the robust conditions needed for a resilient domestic supply chain and a booming secondary manufacturing industry.

The long-term success of this industrial ecosystem in South Africa will ultimately be determined by the strength of its integrated value chain. Partnering with suppliers like Flexicon Africa, who offer the essential, locally supported equipment for safe and efficient bulk material handling, is a non-negotiable step toward securing a competitive edge in the global green economy.

Ready to secure your place in the future of critical minerals production?